Intravenous immunoglobulin (IVIG) is a therapeutic product prepared from the pooled plasma of thousands of donors. Human plasma contains several essential components, including immunoglobulins (Ig), also known as antibodies. Immunoglobulins are important components of the immune system and help the body fight infections.

Ask About IVIG Home Infusion

The process of purifying immunoglobulin from plasma to create patient therapies is complex and time-intensive. It takes approximately 9 months to produce a batch of IVIG products for therapeutic use.

The final IVIG product consists of a mixture of antibodies that are administered intravenously into the patient’s bloodstream.

In this article, we will discuss the series of steps that every manufacturer follows to produce a final sterile solution of IVIG for therapeutic use.

IVIG Production Process

The steps involved in the production of IVIG include plasma collection, fractionation, purification, formulation, testing, and packaging.

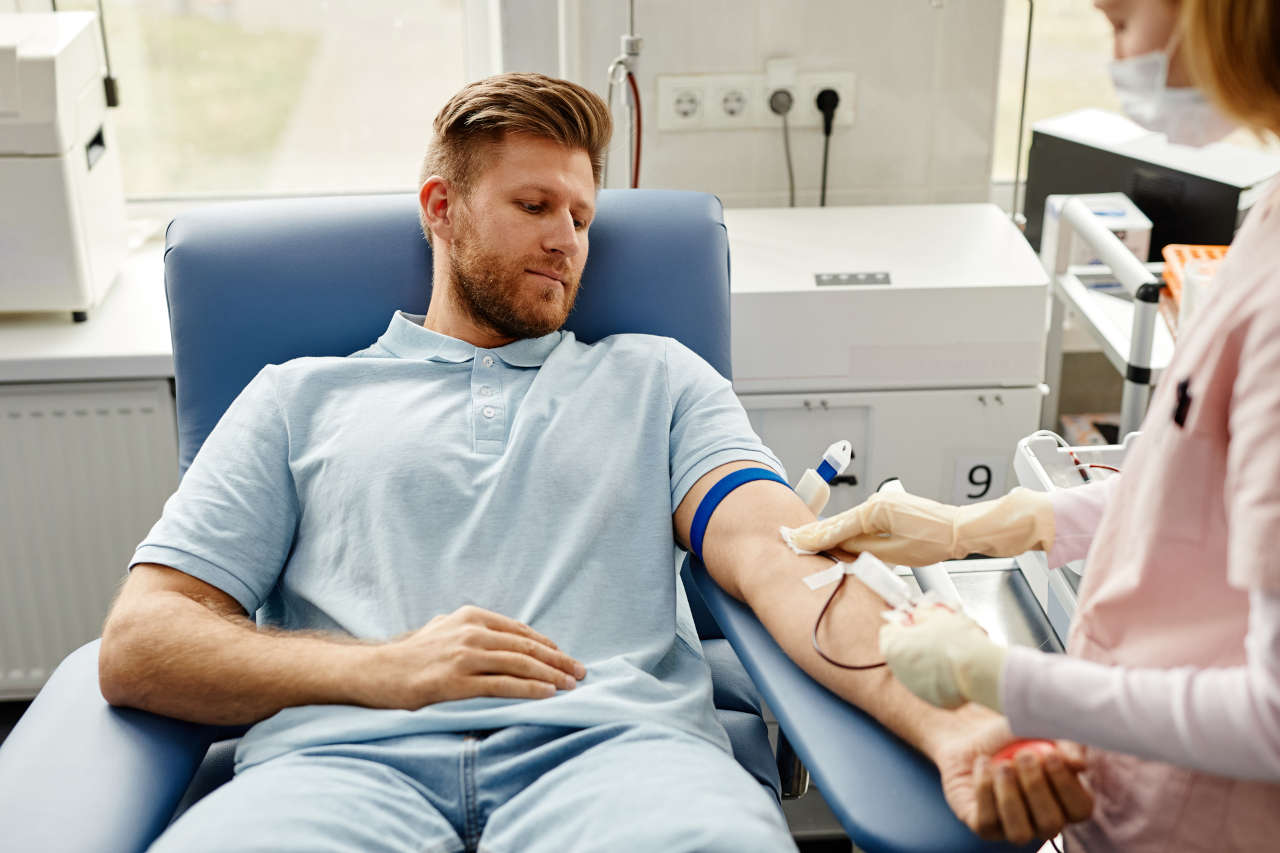

Collection of Plasma

The manufacturing process of IVIG begins with the collection of plasma from thousands of healthy donors. Donors are selected through rigorous screening to ensure the highest quality and safety of plasma.

Plasma used for IVIG production is obtained from two sources: About 20% comes from blood donors, while the remaining 80% comes from plasma donors.

Since immunoglobulins are a small part of plasma, many donations are required to produce enough IVIG to treat patients. For example, producing enough IG to treat one immune-deficient patient for a year takes about 130 donations from healthy individuals.

Plasma Fractionation

After blood plasma collection, a series of fractionation processes take place, during which plasma proteins such as immunoglobulins, clotting factors, and albumin are separated from other plasma components.

Cohn’s fractionation technique, developed by Edwin J. Cohn in World War II, is typically followed, with some newer modifications, to extract a concentrated immunoglobulin solution from plasma. In this technique, small amounts of alcohol (ethanol) are used to reduce pH and ionic strength in order to separate albumin and other plasma proteins based on their solubility.

During the process, the temperature is kept low to decrease the possibility of contamination and allow large-scale fractionation.

Purification of IVIG

Once the immunoglobulins are separated via fractionation methods, rigorous purification ensues to produce a concentrated immunoglobulins solution. The purification process removes inactive proteins, impurities, and contaminants from the solution. For the purification of immunoglobulins, different chromatography methods, such as ion exchange chromatography using DEAE Sephadex®, hydrophobic charge induction chromatography, and size exclusion chromatography, are followed.

Each chromatography technique is unique and yields 95% – 97% of highly purified IgG from small volumes of human plasma in a one-step purification process. For instance, DEAE Sephadex® column chromatography produces a highly purified 95% IgG solution.

In contrast, size exclusion chromatography helps to separate the different forms of IgG immunoglobulin based on their respective size from the pooled plasma.

Furthermore, chromatographic procedures also help to remove an IgA immunoglobulin, which can cause severe anaphylactic shock in patients with IgA deficiency and have anti-IgA antibodies in their blood.

Removal of Harmful Pathogens

Since IVIG is composed of plasma pools from thousands of donors, there is a chance that a virus such as HIV or Hepatitis C may be contained in a sample. Although much care is taken when choosing IVIG donors by completing donor screening and checking donated samples for viruses or bacteria, the use of a fractionation process is vital in obtaining a high level of purity in a sample.

Furthermore, several methods are designed to remove or inactivate the viral pathogens, as follows:

- Solvent/detergent (S/D) treatment inactivates viruses by applying chemicals that destroy their outer coating (envelope).

- Pasteurization is a process in which IVIG solution is heated to 60 ℃ for 10 hours.

- UVC radiation and low-dose radiation methods are used to destroy the virus by attacking its genetic makeup.

- Low pH treatment disrupts the protective layer of the virus and changes protein conformation.

- Nanofiltration is a type of ultrafiltration method in which an IVIG solution passes through a membrane (filter) whose holes are too small for a virus to fit through.

Can IVIG help? | Free IVIG Treatment Info

Formulation and Composition of IVIG

Once IVIG is purified, it undergoes a formulation and stabilization process to ensure its efficacy and stability. Manufacturers formulate and stabilize the IVIG solution by adjusting the pH and adding stabilizing agents such as sugar or amino acids. This step makes each IVIG product differ in terms of formulation and composition.

Final Testing and Packaging of IVIG

IVIG products undergo stringent testing and quality control procedures throughout the production process. A variety of tests and assays are conducted to remove the pollutants, viral pathogens, or prions.

Once the quality control tests are completed, the final product is transferred to vials under an aseptic environment and incubated for several weeks to ensure high quality and safety.

After the final inspection, IVIG is labeled, packaged, and delivered to healthcare facilities for therapeutic use.

Conclusion

IVIG is made from the pooled plasma of thousands of donors, which is then purified through rigorous purification and quality control methods. From the collection of plasma to the formulation of sterile IVIG solution, good collection practices are followed at every step to ensure the product’s safety, efficacy, and quality.

REFERENCES:

- Barahona Afonso, A. F., & Pires João, C. M. (2016). The Production Processes and Biological Effects of Intravenous Immunoglobulin. Biomolecules, 6(1). https://doi.org/10.3390/biom6010015

- Durandy, A., Kaveri, S. V., Kuijpers, T. W., Basta, M., Miescher, S., Ravetch, J. V., & Rieben, R. (2009). Intravenous immunoglobulins – understanding properties and mechanisms. Clinical and Experimental Immunology, 158(Supplement_1), 2-13. https://doi.org/10.1111/j.1365-2249.2009.04022.x

- Knezevic-Maramica, I., & Kruskall, M. S. (2003). Intravenous immune globulins: An update for clinicians. Transfusion, 43(10), 1460-1480. https://doi.org/10.1046/j.1537-2995.2003.00519.x

- Cowden, J., & Parker, S. K. (2006). Intravenous immunoglobulin: production, uses and side effects. The Pediatric Infectious Disease Journal, 25(7), 641-642. 10.1097/01.inf.0000223517.98486.2f